Optimization solution

for inventory deployment

Optimization solution for inventory deployment

Sharing of information on carriers and orders enables flexible deployment and supports highly efficient operation in response to logistics fluctuations.

Daily inventory volume

High-frequency, light-load inventory adjustments can be made by automatically acquiring daily inventory volumes for each location.

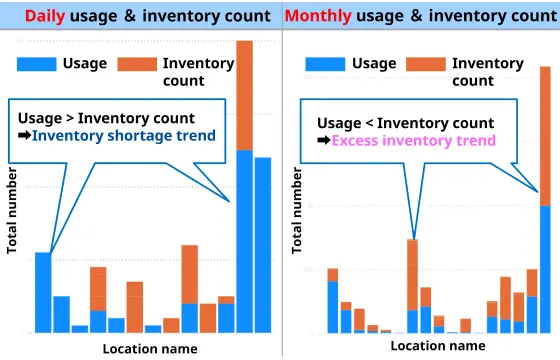

Usage by period

By quantifying the number of items in use and the number of items in inventory at each location, the excess or shortage of inventory in a given period can be checked.

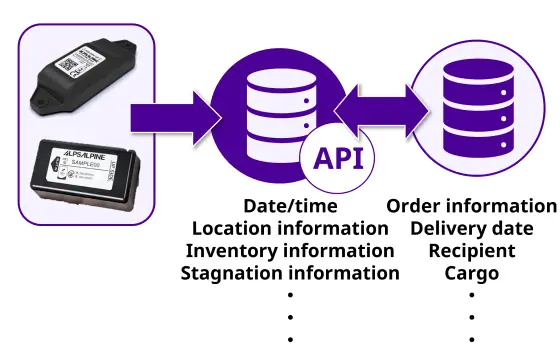

Linkage with commercial distribution information

The combination of customer information and tracker data will lead to further improved logistics efficiency.

Implemented examples

ART SETTING DELIVERY Co., Ltd.

ART SETTING DELIVERY Co., Ltd.

ART SETTING DELIVERY, a company that handles single-person moving and delivery of large furniture and appliances, uses reusable TV packaging materials ("TV cases") to prevent damage to appliances and reduce CO2 emissions by reducing the use of packaging materials. However, there was a need to "streamline the rearrangement, management, etc. of TV cases in accordance with customers' transportation plans," "eliminate backlogs and uneven distribution by understanding their locations," and "understand the utilization rate of each TV case in order to plan appropriate maintenance."

They introduced Alps Alpine's MonoTra™ solution in May 2023, which enables low-cost, high-precision identification of TV case locations, and linking inventory data at each location with transportation plans has led to a significant increase in the efficiency of reassignment instructions. In addition, by improving delivery efficiency through appropriate TV case placement, CO2 emissions from transportation vehicles can be reduced, and by understanding the utilization rate of each individual TV case and promoting appropriate maintenance plans, they have been able to realize a longer service life for the materials.